Description

Introduction

A Pig Signaller is a critical device used in pipeline operations to detect the passage of a PIG (Pipeline Cleaning Tool). PIGs are devices inserted into pipelines for cleaning, inspection (using smart pigs), batching, or other maintenance purposes.

Design Conditions to State for Pig Signaller

OPERATING TEMPERATURE: —20~120℃/Meet customer requirements

NACE MR – 01- 75: Yes

INGRESS PROTECTION: IP65/IP66

CORROSION ALLOWANCE: 3.2 mm/Meet customer requirements

FLANGE RATING: 150#~2500#

WELDED UNDER PRESSURE: 0-25MPa

DESIGN CODE ENVIROMENT: pipeline and trap to ASME B31.4 / ASME VIII‑1, sour service per NACE MR0175 / ISO 15156/Meet customer requirements

BODY MATERIAL : A216 WCB / A105N, 316SS, F51 /Meet customer requirements

CAP & TRIM: SS316

BOLTS & NUTS: A193 B7M & A194 2HM

DEFAULT WETTED PART MATERIAL: 316L

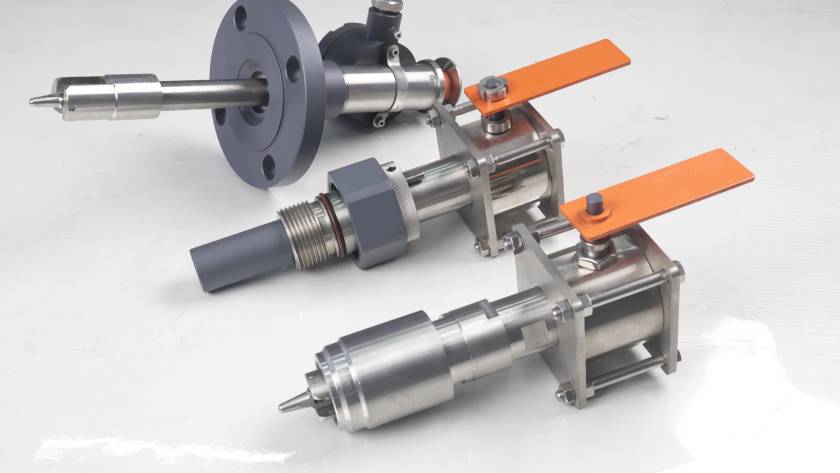

SIX Common Types

- Pig Signaller – flange connection

- Removable Pig Signaller – 2″ NPT Base welded, nipple joint connection

- Removable PigSignaller – 2″Base welded, nipple joint connection

- Removable Pig Signaller – on flange Valve

- Removable Pig Signaller – With A Ball Valve

- Pig Signaller – flange connection 20 mm adjustable

Key Features and Importance

-

Safety and Confirmation: The pig signaller actively confirms that operators have successfully launched the pig, that it is traveling along its route, or that they have safely received it. This prevents accidents (e.g., mistakenly opening a trap while a pig is inside).

-

Operational Control: Allows operators to track the pig’s speed and estimated location. If a pig gets stuck, signallers help pinpoint the last known location for recovery operations.

-

Data Correlation: For “smart pigs” conducting inspections, the pass signal is used to synchronize the collected internal data (like corrosion measurements) with the exact physical location in the pipeline.

-

Visual and Remote Indication: Most signallers have a local visual flag that pops up or rotates, and simultaneously transmit an electronic signal to a control room.

How It Works

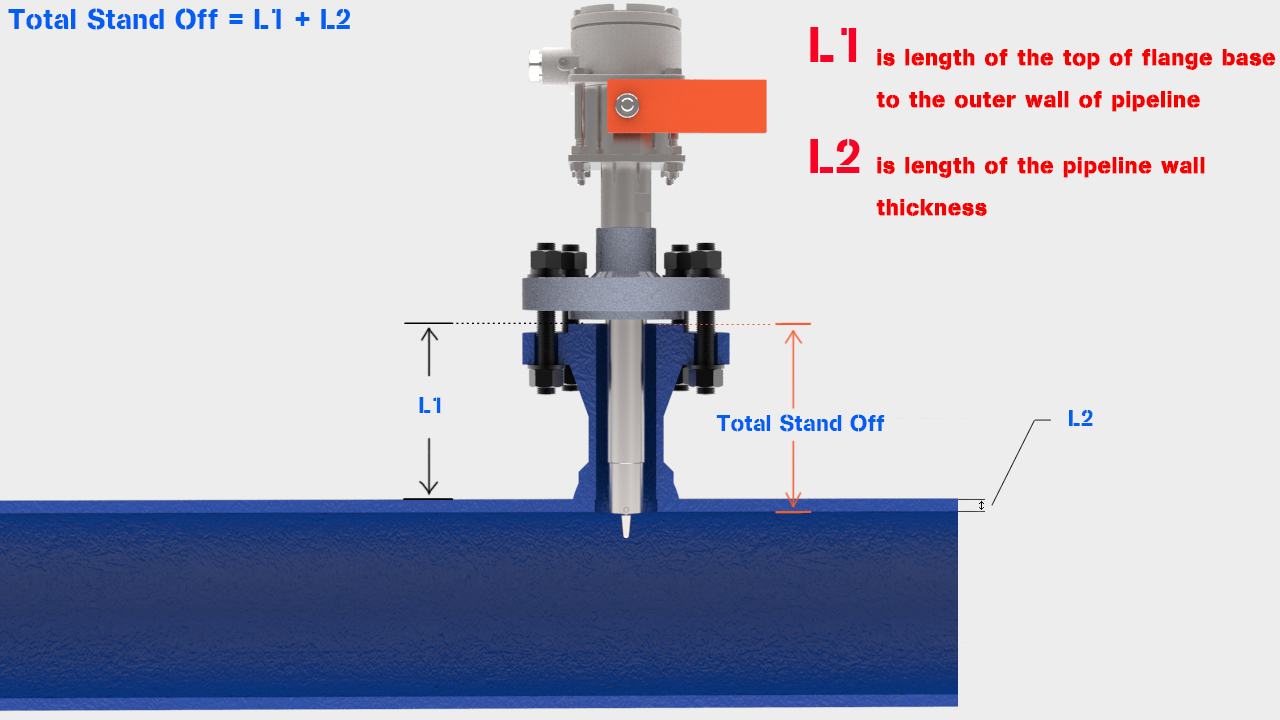

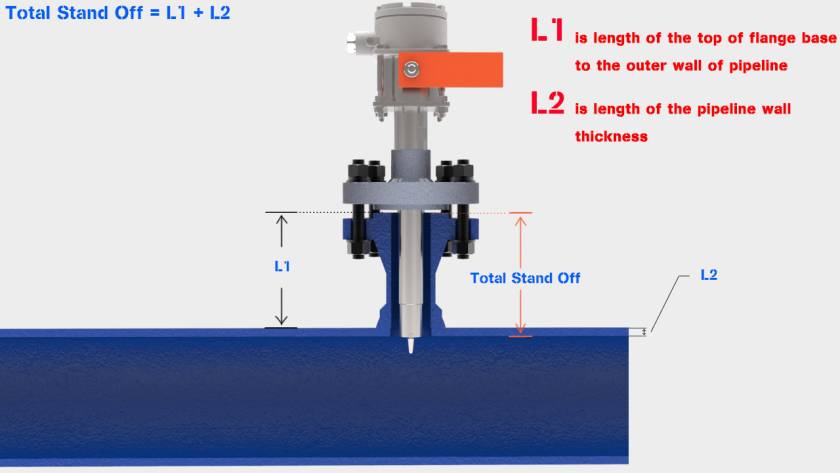

Operators mount the signaller on the pipeline at key locations. These include launch and receiving traps, as well as intermediate checkpoints. Essentially, the device uses one of two sensor mechanisms: intrusive or non-intrusive.

First, the Mechanical/Intrusive Type uses a slender, spring-loaded pin. This pin protrudes directly into the pipe. Then, a passing pig physically deflects the pin. Consequently, this movement triggers an electrical switch. Finally, the switch sends an immediate signal to a control panel.

In contrast, the Non-Intrusive Type is more common today. These systems use external sensors instead. Therefore, they detect the pig without penetrating the pipe wall. For example, common technologies include the following:

a. Magnetic sensors detect disturbances from the pig’s magnets.

b. Acoustic sensors “listen” for the pig’s unique sound signature.

c. Ultrasonic sensors note changes in reflected sound waves.

Reviews

There are no reviews yet.