Description

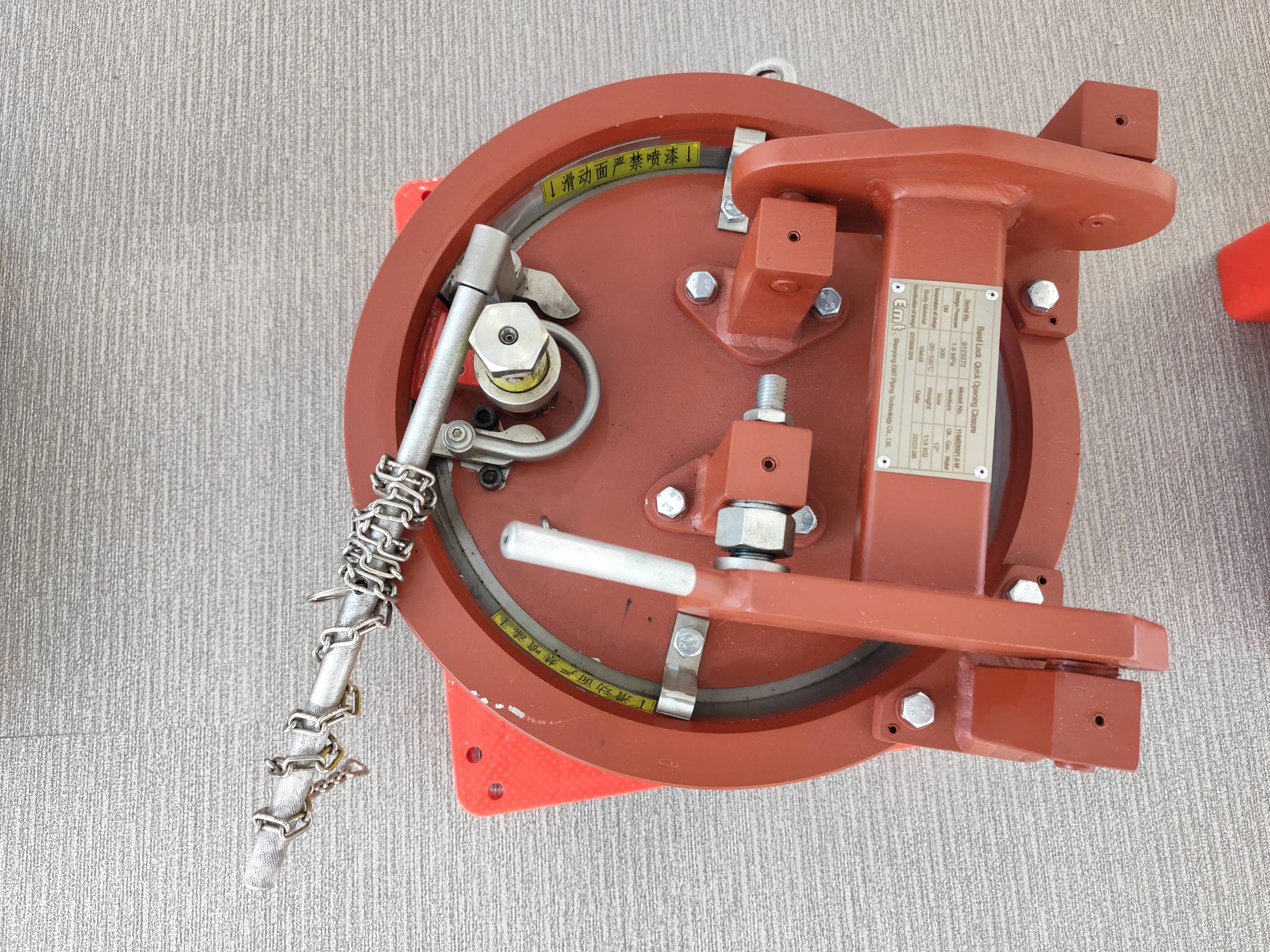

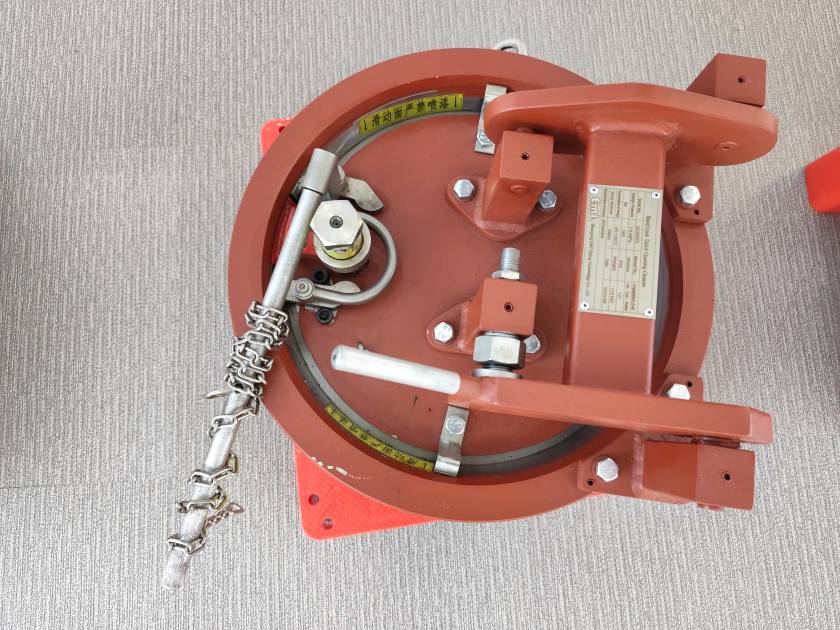

A Locking Band Type Closure is a specialized, quick-opening mechanical device used primarily to securely seal circular openings on pressure vessels, pipelines, and industrial processing equipment. Its design prioritizes operator safety, speed of access, and a reliable pressure seal, making it indispensable in applications requiring frequent opening and closing, such as filters, separators, mixers, and pig launchers/receivers.

Core Principle and Mechanism

Unlike a traditional bolted flange with multiple fasteners, this closure uses a single, unified locking component for a 360° seal:

Primary Components: The system consists of three main parts:

- A vessel body with a machined end.

- A domed lid or cover.

- A duplex stainless steel locking band (also called a conical thrust ring).

The Locking Action:

- The locking band is a precision-engineered, segmented or solid ring that fits into a matching internal groove on the vessel body. When the closure is in the locked position, this band rides over the lip of the lid, mechanically preventing it from opening. The conical design of the band ensures the pressure force is distributed uniformly around the entire circumference, creating a robust and balanced seal.

Key Characteristics and Advantages

Rapid Operation: The single locking band mechanism enables operators to manually open or close the vessel in under a minute without specialized tools, drastically reducing downtime for inspection, cleaning, or maintenance.

Intrinsic Safety: Safety interlocks integrate into modern locking band closures. These critical mechanisms physically prevent operators from disengaging the locking band while internal pressure remains in the vessel, eliminating the risk of a hazardous blow-off.

Self-Acting Seal: The closure employs a lip seal or O-ring located in the lid. Under internal pressure, this seal is forced tighter against the sealing surface, creating a self-energizing, leak-proof barrier that increases in effectiveness as pressure rises.

Robust and Reliable: Made from high-strength materials like duplex stainless steel, the locking band provides a full-perimeter load distribution, offering a secure closure capable of withstanding high pressures and cyclic loads.

Typical Applications

Typical Applications

Locking band closures are the preferred choice for quick access on:

- Pressure Vessels & Reactors

- Pipeline Pig Launchers and Receivers

- Industrial Filters and Strainers

- Mixers and Blenders

- Any process vessel requiring frequent, safe, and fast access.

Parameters

| Name | Details |

| Closure Type | Locking Band Type |

| Installation | Horizontal/Vertical |

| Opening Direction | Left/Right |

| Material | Carbon Steel/Based on the information provided by the client |

| Corrosion Allowance | 3mm/Based on the information provided by the client |

| Design Pressure | Based on the information provided by the client |

| Hy.T.Pr.=1.5xDesign Pressure Mpa(Psig) | Based on the information provided by the client |

| Design Temperature | Based on the information provided by the client |

| Seal Material | Gasket is of self-energized type &seals shall be resistant to explosive decompression and suitable for hydro carbon service. (Sour). |

| U Stamp | Provided |

| Spare Parts & Special Tools | Min 2 nos door seal / closure. (Material Comply with NACE, hydrocarbon and H₂S) |

| PMI required for Stainless Steel Material | Provided |

| NB Registration | Yes |

Reviews

There are no reviews yet.