Description

1. Introduction

The EMT Non-Intrusive Pig Signaller is a vital tool for the pipeline industry, designed by EMT Pigging to ensure the efficient and accurate detection of pigs as they travel through pipelines. This device is crucial for maintaining the continuous operation and safety of pipeline systems used across various industries, including oil and gas, wastewater, and chemicals.

2. Key Features and Specifications

- Brand Name: EMT Pigging

- Model Number: SN2-TQZ

- Product Name: Flange Pipeline Pig Indicator with Ball Valve

- Application: Designed specifically for pipeline systems, it is used to detect the presence of different types of pigs—foam pigs, metal-bodied pigs, polyurethane pigs, spheres, and mandrel pigs.

- Indicator Type: Offers both manual reset flag and electrical switch options, providing flexibility in monitoring and signaling.

- Flange/Body Material: Available in a variety of materials including PTEF Coated A105N, 304SS, 316LSS, DSS, and INCONEL, allowing customization according to specific environmental conditions and requirements.

- Installing Type: Compatible with ASME B16.5 2” flange and API 1 13/16″ flange, ensuring easy integration into existing pipeline systems.

- Design Pressure: Handles pressures up to ANSI 2500# and API 10000 Psi, suitable for high-pressure applications.

- Operating Temperature: Functional within a range from -20℃ to +120℃, making it reliable in extreme weather conditions.

- Certification: ISO9001 certified, ensuring compliance with international quality standards.

- Features: High accuracy and low cost, the signaller is equipped with features like the ability to be removed under pressure, adding a layer of versatility and safety.

3. Operational Flexibility and Maintenance

01 Operational Flexibility

- Compatibility with Existing Infrastructure:

One of the standout features of the EMT Non-Intrusive Pig Signaller is its ability to be installed on the majority of existing signaller bosses. This compatibility is extremely beneficial for retrofit projects as it eliminates the need for extensive modifications to existing pipeline systems. Companies can upgrade their pig detection systems without the costly process of replacing or extensively modifying existing pipeline components.

- Versatile Mounting Options:

The device offers several mounting options, including 2” flange connection, 2” welded nipple, and 2” welded base-NPT nipple connection. These options provide flexibility in how the signaller can be integrated into different types of pipeline configurations, whether it’s a new installation or an upgrade to an existing line.

- Material Selection for Various Environments:

With a range of materials like PTEF Coated A105N, 304SS, 316LSS, DSS, and INCONEL, the signaller is suitable for various operational environments. Whether it’s a highly corrosive environment or one that requires robust materials for high-pressure handling, this signaller can be customized to meet those specific requirements.

02 Maintenance Advantages

- No Dynamic Seals:

The design of the EMT Non-Intrusive Pig Signaller avoids the use of dynamic seals. This is a significant design choice as dynamic seals are prone to wear and tear and can be a common point of failure in pipeline equipment. By eliminating these, the signaller reduces the risk of leaks and failures, thereby enhancing the reliability of the pipeline monitoring system.

- Ease of Maintenance:

The absence of dynamic seals not only reduces the risk of operational failures but also simplifies the maintenance process. Routine checks and maintenance become less cumbersome and less frequent, which helps reduce maintenance costs. The simple design allows for easy access to replaceable parts, if necessary, without requiring complete disassembly or specialized tools.

- Long-Term Operational Cost Reduction:

The initial design considerations focusing on compatibility, ease of maintenance, and material durability contribute to a significant reduction in long-term operational costs. By extending the intervals between maintenance, reducing the likelihood of system failures, and allowing for easy upgrades and replacements. The signaller ensures that operational budgets are focused more on productivity rather than repairs and downtime.

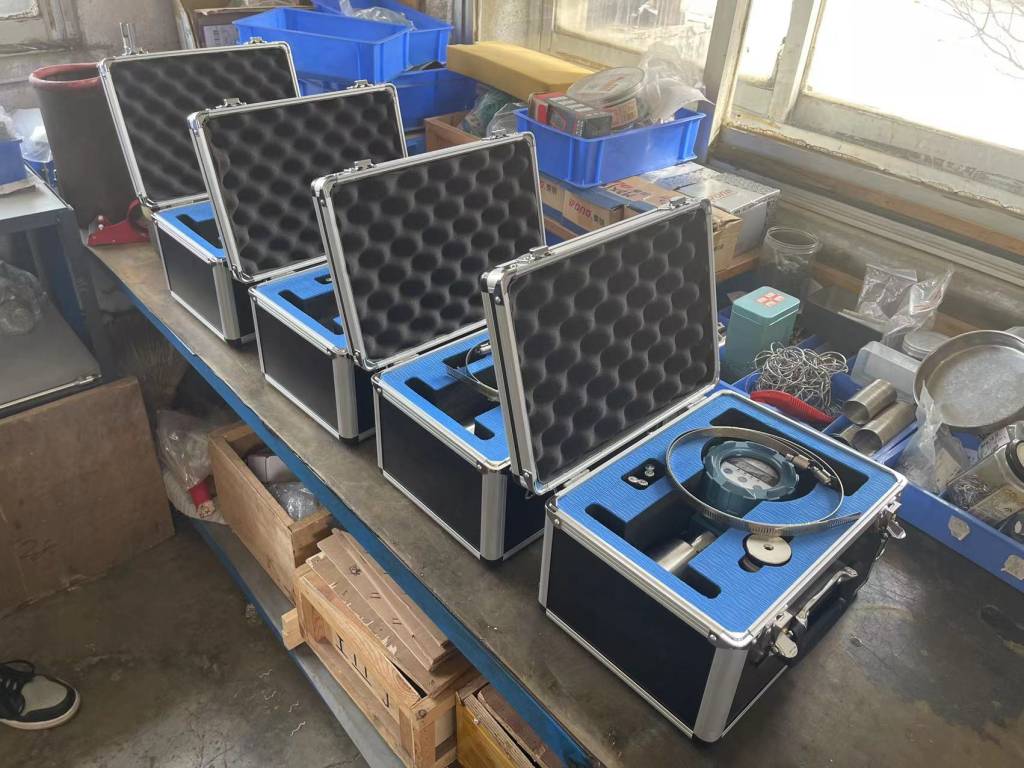

4. Packaging and Delivery

-

Packaging Details

- Material Selection for Packaging: The packaging materials are chosen based on their ability to withstand various stressors such as impacts, moisture, and temperature variations. This may include durable corrugated cardboard, foam inserts, or other cushioning materials that protect the device during shipment.

- Gross Weight Considerations: The total gross weight of the package is 8.000 kg, making it manageable for handling and transport. This weight includes all the necessary protective packaging, ensuring that the device remains secure throughout its journey to the client.

- Customized Packaging Options: For clients with specific packaging requirements, EMT Pigging offers customized solutions. Whether it’s the use of environmentally friendly materials or additional protective layers for extremely sensitive environments, EMT Pigging can adapt to meet these needs.

Delivery Options

- Customized Support (OEM and ODM): EMT Pigging excels in offering Original Equipment Manufacturer (OEM) and Original Design Manufacturer (ODM) services. This means that the pig signaller can be customized not only in its functionality and compatibility with various pipeline systems. But also in its branding and design to meet the specific requirements of customers.

- Global Shipping Capabilities: EMT Pigging has established shipping capabilities that allow for the delivery of the pig signaller globally. So this includes partnerships with major logistics providers to ensure timely and efficient delivery to remote locations.

Reviews

There are no reviews yet.