Description

EMT’s Polyurethane Pigs represent a pinnacle of innovation in pipeline maintenance technology, engineered to meet the diverse needs of industries including building materials, construction, energy, mining, and oil & gas pipelines. These pipeline pigs have meticulous design to ensure optimal performance in pipeline cleaning, drainage, water resistance, and dielectric isolation.

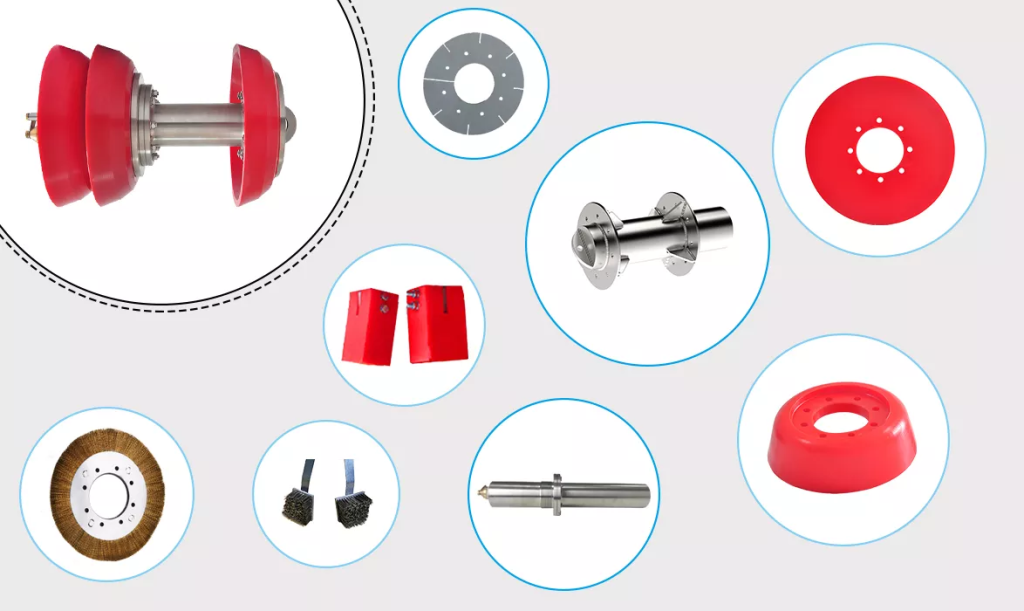

1. Design and Material Attributes

The EMT Polyurethane Pigs are constructed with a focus on durability, efficiency, and adaptability. Available in sizes ranging from 2 inches to 60 inches, these pigs have good design to accommodate a wide array of pipeline diameters, making them versatile tools for various pipeline applications. The body of the pig features a steel mandrel, which can be either carbon steel for standard applications or stainless steel for more corrosive environments, ensuring the pig’s longevity and reliability.

The choice of polyurethane or fluorocarbon (FKM) for the cup materials offers flexibility in terms of chemical compatibility and temperature resilience. Polyurethane is famous for its excellent wear resistance and flexibility, making it ideal for general scraping and cleaning tasks.

2. Operational Efficiency

EMT’s Polyurethane Pigs have good design to deliver maximum cleaning efficiency with minimal maintenance. The four-cup design enhances the sealing and sweeping action, enabling the pig to effectively remove debris, scale, and other deposits that can accumulate in pipelines over time. This design also allows for a good bypass of fluid, aiding in the pig’s movement and preventing it from becoming stuck within the pipeline.

With a starting pressure range of 0.2 to 0.3 MPa and the ability to travel approximately 100 kilometers, these pigs are capable of long operational runs without requiring intermediate stops for adjustment. This capability is particularly valuable in extensive pipeline systems where continuous operations are critical to maintaining flow and preventing downtime.

3. Applications Across Industries

EMT’s Polyurethane Pigs are essential tools in the pipeline industry, transcending beyond mere cleaning to serve multifaceted roles across various operational contexts. These pigs have meticulous design to address critical needs in pipeline maintenance, ensuring optimal operational efficiency, safety, and integrity. Here’s a detailed exploration of their applications across different industries:

⑴ Pipeline Pigging for Enhanced Flow Efficiency

The primary application of EMT’s polyurethane pigs is in pipeline pigging, where they are instrumental in maintaining clear, unobstructed pipelines. Regular pigging is crucial for the prevention of blockages and buildup of deposits like wax, scale, or other sediments. These blockages, if left unchecked, can lead to decreased flow efficiency, increased pressure, and even pipeline rupture. By integrating EMT pigs into routine maintenance schedules, companies can ensure that their pipelines operate at peak efficiency, minimizing downtime and enhancing the overall safety of the pipeline systems. This is particularly vital in industries such as oil and gas, where the smooth flow of products is essential to operational success.

⑵ Drainage and Dewatering Capabilities

Following hydrostatic testing—a method used to validate the integrity and strength of pipelines—there is often a significant amount of residual water and condensate. EMT’s polyurethane pigs have good design to effectively clear these fluids from the pipelines. The importance of this function cannot be overstated, as leftover moisture can lead to internal corrosion, scale formation, and other moisture-related damages that compromise pipeline integrity. So in industries like water treatment and chemical processing, where ensuring the dryness of pipelines is crucial, EMT pigs provide an indispensable solution.

⑶ Water Resistance for Pipeline Integrity

EMT’s polyurethane pigs also play a crucial role in enhancing the water resistance of pipelines. The robust construction of these pigs provides an excellent barrier against water ingress, which is essential for maintaining the dryness and functionality of internal systems. This feature is particularly beneficial for subsea pipelines and those in moist environments where the risk of water entering the pipeline system is high. By preventing water ingress, these pigs help in preserving the structural integrity of pipelines and preventing the internal components from water damage.

4. Quality Assurance and Compliance

Each EMT Polyurethane Pig is backed by a six-month warranty, underscoring the manufacturer’s confidence in the product’s quality and durability. The ISO9001 certification of these pigs guarantees that they meet international quality standards, providing further assurance of their reliability and performance.

In addition, each pig undergoes rigorous testing, including video outgoing-inspection and a detailed machinery test report, ensuring that every unit delivered to the field operates at peak performance levels.

Reviews

There are no reviews yet.